GENERAL

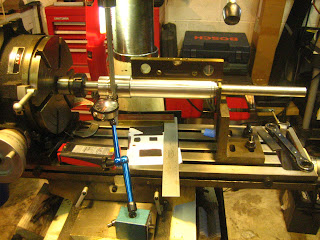

After all this time the testing begins. Shown here is the prototype frame with the mount and the first, of three, W52 barrel-receivers to test. The frame has been revised three times since the one shown here; however, the concept remains identical. Really, this is the cullmination of three years of effort on my behalf and considerable engineering activities. Initially, my efforts were with the Federal 711B, which the shooting community consensus seems to denigrate. This formed my baseline. Things must get better from this baseline. This investigation is NOT designed to test the ammunition but the barrel-receiver combo vs ammunition.

The absolute goal is to compete prone, while I still can; however, my intention is to be competitive and the Sitman stocked Win 52 is not even close, which involved more than a year to accomplish. First of all Alex Sitman is not known to be quick or punctual; however, the results are uncompromised and I possess a high respect for his work ethic and honesty. Essentially, I know I must rebarrel the Sitman W52; but I can just "drop in" a barrel action combo for my own practice and I'm running out of time. Later I will add a Shillen barrel. Bill Blankenship, 8 time US bulleye champion who I was fortunate to meet, once told me not to practice with unknown and questionable gear. So I had Jim Clark build me 3-1911's over a 5 year period, two of which I have sold. Getting back to the W52:

http://www.accurateshooter.com/guns-of-week/22lr-rimfire-ammo-comparison-test/

The results are fascinating to say the least. The tester observed: “I got some amazing groups, and some which are, frankly, are absurdly bad! This has re-enforced what I had experienced with 22 ammo in the past — that is being consistently inconsistent.”

The procedure utilized was based upon a thorough general testing of more than 100 types of 22LR in very "sanitized" conditions. See the Accurate Shooter link above.

CONDITIONS

Over a period of 2 weeks and three days of testing 1) concept evaulation 2) FED 711B testing and 3) selected available brands carried by Midway USA. The distance is 100 yds. The weather was great: 60^ to 80^ with winds less than 8 mph at ground level. September 15, 2012 and September 22-23, 2012.

20 shot groups were observed, although at times I miscounted and the count was 18 or 19. Standard deviation was computed for the group, center of mass and error from the mean. The position of each round was measure to within .003". One brush through the bore every 20 rds. Yes, this is achievable and here is how.

Here is a Remington Target 1080 fps. I never did reproduce this after this group. The light line to the left of the scan is exactly 3.000" + or - 0.015". Very symmetrical. The Rem round is very tight in the W52 chamber, any W52 chamber. It is dirty. I have fired several thousand, waste of money, and time, which I do not have.

The pixel size is 0.003". The green dot is the center of the group. The dotted lines are one standard deviation.

Rem 09/15/12

Rem 09/15/12

del X delY

1 240741.034 239937.067 0.391 -0.988

2 240740.917 239936.776 0.508 -0.697

3 240740.749 239936.540 0.676 -0.461

4 240740.987 239936.279 0.438 -0.200

5 240741.143 239936.426 0.282 -0.347

6 240741.539 239936.754 -0.114 -0.675

7 240742.045 239936.577 -0.620 -0.499

8 240742.072 239936.342 -0.647 -0.264

9 240741.970 239936.233 -0.545 -0.155

10 240741.660 239936.108 -0.235 -.029

11 240741.360 239935.913 0.065 0.166

12 240741.556 239935.860 -0.131 0.219

13 240741.625 239935.829 -0.200 0.250

14 240742.299 239936.100 -0.874 -.021

15 240741.776 239935.634 -0.351 0.444

16 240741.553 239935.551 -0.128 0.527

17 240740.597 239935.615 0.828 0.464

18 240740.477 239935.919 0.948 0.160

19 240741.405 239934.950 0.020 1.129

20 240741.735 239935.104 -0.310 0.975

4814828.4985 4798721.576

Left Dn

240741.424 239936.0788 -0.8743 -0.9880

0.9475 1.1292

0.4975 0.5345 Right Up

Extreme Spread 1.8218 2.1172 inches

From the above and based upon this group, 66 2/3 out of 100 of the shots should be 0.498" left or right and 0.534 inches up or down from the center of the group and extreme spread 1.82" and 2.12" respectively. This score is 199-4X if held perfectly. And the next 20 rds in that box, much less the next box, who knows?

How did I do this?

Each target was scanned at 300 dpi. The scanned document was loaded into Bentley's Microstation V8 Series 1 (Autocad has the same capabilities). A program written in Microsoft Visual basic then interrogated the file and extracted the coordinates in inches and the Cg computed and the other characteristics developed. Press the "Easy" button.m Well for one group.

TEST FRAME

The test frame evolved for more than a year and I will discuss some of the assumptions devised during the use thereof. But first a limited portion:

711B 09/15/12 STDx STDy delX delY

0.6132 0.6731 2.1022 2.5787

0.6170 0.5299 2.2099 2.0216

0.5346 0.9687 1.9126 3.4397

Rem Target 0.4976 0.5345 1.8218 2.1172

RWS 0.4651 0.4416 1.5126 1.4548

WIN T22 0.4837 0.8626 2.0810 3.3120

Laupa CentX 0.4592 0.3998 1.5367 1.9374

ELEY TEAM 0.5524 0.3374 1.9518 1.0745

FED um22 0.4018 0.4083 1.4279 1.5819

FED 922A 0.4484 0.4559 1.7888 1.6606

FED 922A 0.4484 0.4559 1.7888 1.6606

922A w/bbl 0.6115 0.5230 2.2507 2.1063

tuner

From this stage VarmintAL pages gave me guidance with his deterministic evaluation of a 22LR with and w/o a tuner. Originally, my hope was I could "tune" one of the W52 action-barrel. He did not perform verification of his model as stated elsewhere; but, I am not a novice at finite element analysis, albeit from a structural design environment. Material mechanics is an entire different discipline. Whereas structural is based upon "satisfactory performance", engineering mechanics ascertains actual conditions. I bow to his expertise.

look at the final frame:

This picture is "busy"; this was the last day of testing. Beneath the shop rag is a 95 lb lead weight. I made another one, 53 lbs, for the front leg and then added the 2" structural angle as a diagonal brace. All these modifications intended to add stiffness to the frame. Without the barrelled action, the frame does not exhibit, after a good "whomp" any sustained vibrations, so it alone is independent. Add the barrelled action, give it a "whomp" and the vibrations dampen for 2 seconds.

|

| Receiver-Frame Connection Figure-XX |

All of this is dependent upon the bullet exit time. Look at the RWS above data, about 1200 fps. This was a minimal group, only 10 rds (all I had). 3 rds were fliers, but look at the other hits. So maybe the time of flight has improved based upon the naked barrel harmonics. This round deserves more investigation.

To the right is a photo of the action connection to the frame. As discussed elsewhere, the rear of the W52 action has minimal stiffness. The open frame cannot reduce this deficiency; whereas the Eliseo stocked W52 will engage the cylinder. Qualitatively, the barrel harmonics will be subsequently reduced. Maybe AL can tell me how much. This avenue is not complete and I will add more info.

Futhermore, the open frame may have exerbated the rear bolt weakness. See Fig XX.

The above will be my final condition and the rear screw affect will be minimal; thus the conditions tested herein are the

before condition.

Also, from the above data, the receiver-barrel tested will not get me into the top 5. Most likely I will have to rebarrel.

First I am going to test one more action.

Then try to compensate the barrel harmonics with a tuner using the high velocity and low velocity methodology discussed on Accurate Shooter forum.

These items to come in a subsequent post.

ABSOLUTE FIXITY IN A TEST FRAME

Lastly.

Consider the absolutely rigid mount (as I have devised here) for a moment vs. the bench rest shooting community. Once again, fixity (if possible) would resemble the testing performed in England by a 22 ammo manufacturer. Their testing clamped a barrel in a solid steel frame attached to concrete. The action was aft of the clamp and only 18" of the barrel protruded. The postulation was measurement of the barrel end frequency with light. Now, this would be very rigid boundary conditions. Even the barrel was shortened and thus subject to high frequencies.

Did I do this very same thing, albeit a flexible barrel? I dont know.

Bench rest shooters slide on rails, on special front rests, on special bags to specific density. Only the trigger finger and the shoulder touches the rig. They shoot groups the size of the 22 projectile under consideration herein.

In retrospect, let us consider the frame I have devised. But the connections are elastic. Between 2 plates of stainless steel, we bond an isolation rubber, i.e. laminated elastomeric bearing. The plywood shown in the photo is replaced by this bearing(s). The clamp would be justapositioned above the bearing. I think this is the way VarmintAl is modeling his boundary conditions. Well worth the modification.

See:

http://winchester52.blogspot.com/2012/09/continued-testing.html

It seems as though my overactive engineering mind overestimated the degree of fixity. The comments above are valid theoretically, the magnitude did not affect final result.

Added 10-05-2012 9:05 AM

The above concerns are not an 'overactive engineering mind' as discovered by others and hundreds of man-hrs have been devoted to analysis.

See:

http://www.varmintal.com/ for thorough compendium on deterministic prediction of muzzle movement and orientation. This study helps us visualize the parameters involved and the relative affects.

For actual testing see:

http://www.border-barrels.com/articles/rimfire_accuracy/tuning_a_barrel.htm

http://www.border-barrels.com/articles/rimfire_accuracy/velocity_dispersion.htm

The latter is a long discourse concerning the vibrations of a "fixed" base such as I have constructed. My thoughts on the elastomeric connections was incorporated.

My goal is to find a combination of ammo-receiver-barrel that will amke me competitive. One thing I have learned: there may be a seperate setup for 50 yds.

to Quote:

The test rig had been built to be a rigid 'barrel vice', but it was plain that bottom plate flexed due to the recoil force. When looking through the scope (attached to the top of the barrel clamp) the picture would 'jump' noticeably when the rifle was fired.  It was of concern that the recoil energy in the test rig was being dissipated in an unpredictable fashion into barrel vibrations that were affecting the group. In an effort to control the recoil energy in a predictable way, the Border Barrels Recoil Pressure Gun was adapted to make a free recoil test gun. With this gun, the recoil is constrained to be straight back, with the recoil energy being dissipated in friction by the linear slides on the rods and in the hydraulic damper seen at the back of the rig. The carriage is designed so that the centre of gravity of the recoiling mass is approximately on the bore line, so minimising any rotational moments when recoiling which might affect the launch angle of the bullet. Groups with this free recoil rig were initially disappointing as they formed vertical strings. The barrel and action were indexed 90 degrees to the left and to then to the right, but the groups produced were always strung vertically. Any systematic problem with the barrel and action was thus ruled out as the cause of the vertical stringing.

It was of concern that the recoil energy in the test rig was being dissipated in an unpredictable fashion into barrel vibrations that were affecting the group. In an effort to control the recoil energy in a predictable way, the Border Barrels Recoil Pressure Gun was adapted to make a free recoil test gun. With this gun, the recoil is constrained to be straight back, with the recoil energy being dissipated in friction by the linear slides on the rods and in the hydraulic damper seen at the back of the rig. The carriage is designed so that the centre of gravity of the recoiling mass is approximately on the bore line, so minimising any rotational moments when recoiling which might affect the launch angle of the bullet. Groups with this free recoil rig were initially disappointing as they formed vertical strings. The barrel and action were indexed 90 degrees to the left and to then to the right, but the groups produced were always strung vertically. Any systematic problem with the barrel and action was thus ruled out as the cause of the vertical stringing.

However, the barrel is vibrating before the bullet leaves the barrel. How we compensate is endless. This discussion used only two types of ammunition. The 1/2" plate they used is flexible; my frame is flexible. However, I look at this in another manner. The frame(s) are very rigid; but the induced vibrations intiated by the burning gases transmits forces to the frames(s). Stocked and in the shooters hands, the results are more compliant. Consequently, we have only scratched the surface in 80 years for 22 RF.

End edit 10-05-2012.

A NOTE ABOUT W52 BOLT REMOVAL AND REPLACEMENT

This topic is covered in many places; in no instance have I found an easy solution. One aspect is to understand the trigger. Look at this:

Everyone can remove the bolt, even in competition. So how do you get the blasted thing back in the receiver? Push the easy button.

Look at the Photo to the right.

FIRST you must pull on the trigger to release the disconnector with right hand.

Second, hold the bolt in the right hand and aligned keeping finger on trigger.

Third, take the index finger of the left hand and with the nail down.

- Fourth, Insert the finger into the receiver finger pointed to the rear.

Fifth, depress the top trigger lever with the thumb nail.

Sixth, with the right hand, while holding the trigger back, slide the bolt handle forward.

This method was taught to me by the Army sargent supervising the UoA Cadet range. It takes practice. It works every time.

Mike

All rights reserved.